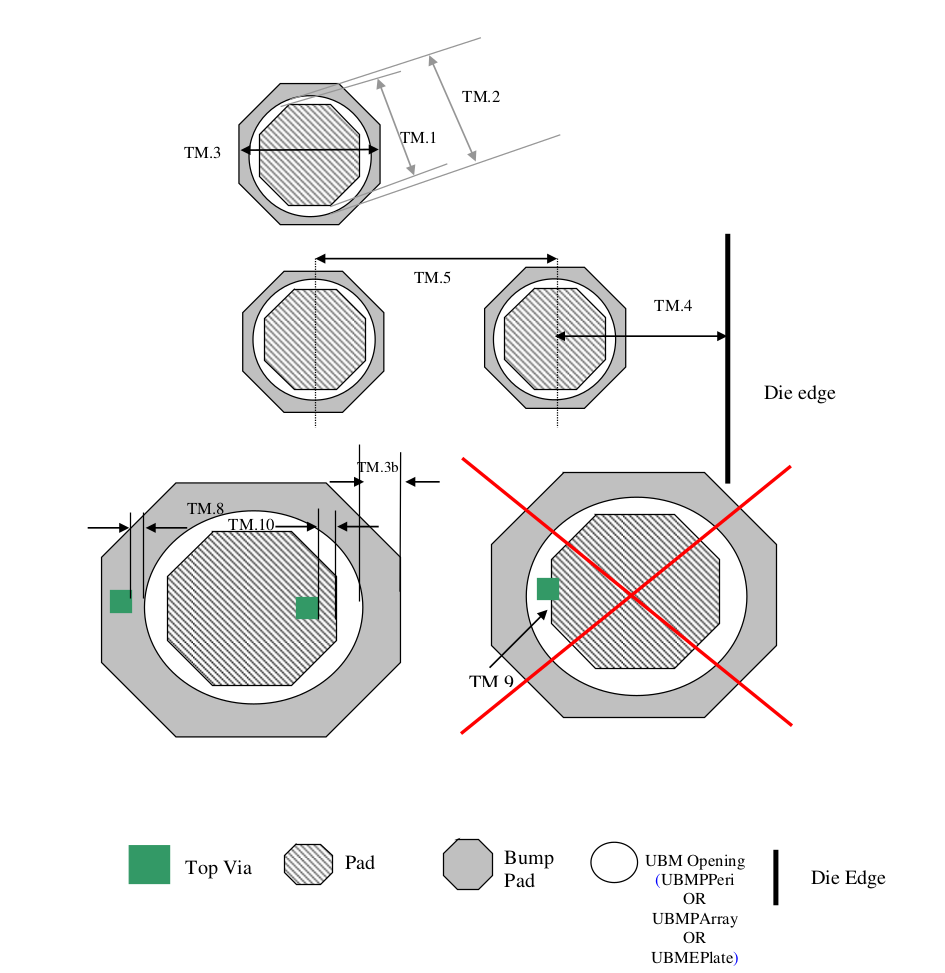

9.4.3 Solder Bump Pad design guidelines¶

This section contains the bumping design guidelines for flip chip applications

Top Metal (Al)

NO. |

DESCRIPTION |

LAYOUT RULE |

TM.1 |

Passivation Opening (Pad mask) |

A |

TM.1a |

Min Passivation Opening |

40 |

TM.2* |

UBM Opening |

A+20 |

TM.2a |

Min UBM Opening (defined by the layers UBMPPeri or UBMPArray or UBMEPlate layers depending upon the process) |

60 |

TM.3 |

Bump Pad (Top metal in this case) |

A+32 |

TM.3a |

Min Bump Pad |

72 |

TM. 3b* |

Bump Pad larger then UBM Opening |

6 / per side |

TM. 4 |

Space from centre of Pad to Die Edge (Outer edge of GUARD_RING_MK marking) |

90 |

TM. 5 |

Min allowable bump pitch |

>= 70 + (1.3*TM.2) |

TM.6 |

Pad without UBM layers is not allowed except the Pad under PROBE_MK marking. |

Not allowed |

TM.7 |

Shape of the Pad shall be at least octagonal (or more closer to circular) except the Pad under PROBE_MK marking. |

DRC check |

TM.8 |

Space from edge of top via to the edge of UBM opening |

2 |

TM.9 |

Partially overlap of top via with passivation opening is not allowed |

DRC check |

TM.10 |

Space from edge of top via to the edge of passivation opening |

2 |

Note

* Use tolerance of 0.2um for DRC check.