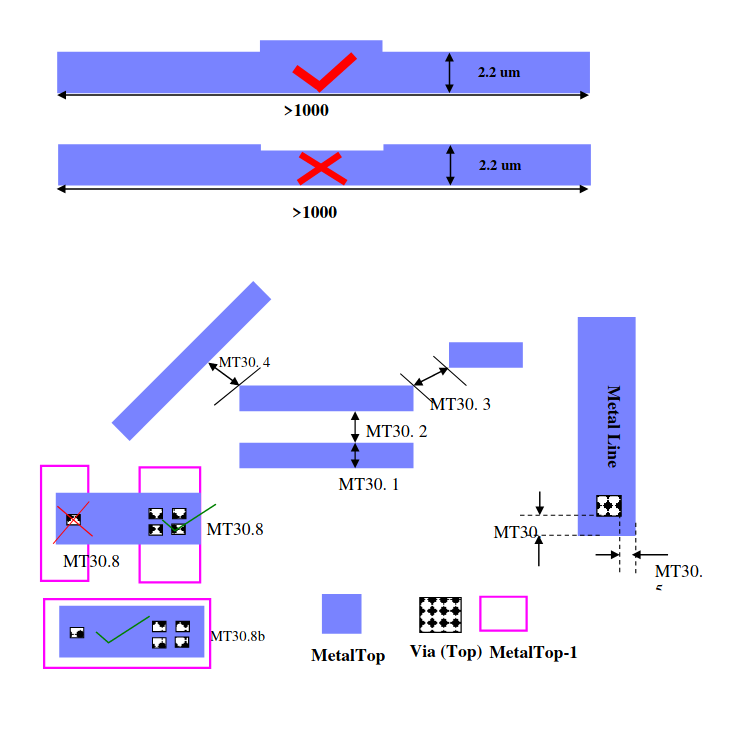

7.16 3.0um Thick MetalTop Option¶

This section describes the design rules for 3um thick Aluminum MetalTop design rules.

RULE NO. |

DESCRIPTION |

LAYOUT RULE |

Layer |

MT30 = 3um Metal Top |

|

MT30.1 |

|

1.8 2.2 |

MT30.2 |

Min. thick MetalTop space |

1.8 |

MT30.3 |

The separation of two corners should satisfy the minimum spacing |

1.8 |

MT30.4 |

The separation of single metal line from a any degree metal line should satisfy the minimum spacing |

1.8 |

MT30.5 |

Minimum thick MetalTop enclose underlying via (for example: via5 for 6LM case) [Outside Not Allowed] |

0.12 |

MT30.6 |

Thick MetalTop end-of-line (width <2.5um) enclose underlying via (for example: via5 for 6LM case) [Outside Not Allowed] |

0.25 |

MT30.7 |

Thick MetalTop coverage over the entire die shall be >30% (Refer to section 13.0 for Dummy Metal-fill guidelines. Customer needs to Ensure enough dummy metal to satisfy Metaln coverage) |

|

MT30.8a |

As via size compare to min thick-metal width is very small. Single top via (e.g Via3 for 4 layer metal process with 3.0um thick top metal option. in other words via connecting to thick metal) At one location cannot exit under the thick (3um thick) metal. |

DRC check |

MT30.8b |

There shall be minimum 2X2 array of vias (top vias) at one location connecting to 3um thick top metal. Note: This rule will not checked for seal ring area (identified by GUARD_RING_MK As the via rules in this area are separately covered under seal ring section) |

DRC check |